500kg/h 1000kg/h Industrial fully automatic frozen potato french fries frying production making machine line equipment

1.Low energy consumption, high output

The degree of automation is high, and the efficiency is significantly improved. The French fries made have uniform appearance, less material, consistent taste, not easy to change color, well-preserved nutrition, energy saving and environmental protection.

2.Health and Safety

All equipment (parts in contact with materials) are made of stainless steel, easy to clean and hygienic.

3.Runs Smoothly

The electrical accessories of the whole machine are all well-known brands that have passed the market test, with guaranteed quality, low failure rate and long service life.

4.Customized

According to the customer's workshop, there are also customized services for production requirements.

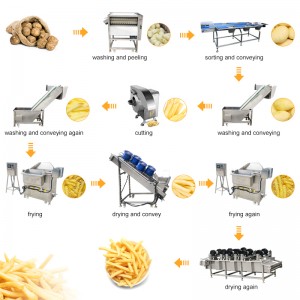

Classification and specific introduction of quick-frozen french fries production line:

Raw potatoes →Loading elevator→ Washing and peeling machine → Sorting conveyor line →Elevator→Cutter →Washing machine →Blanching machine→Cooling machine → Dewater machine → Frying machine →Deoiling machine→Peeking conveyor line → Tunnel freezer →Automatic packing machine

The main process of the quick-frozen French fries production line is briefly described as follows:

(1) Presetting of raw materials In order to extend the processing cycle, potato raw materials must be stored for a long time. After long-term storage of raw materials, their sugar content and nutritional components will change to a certain extent. Therefore, a certain period of recovery treatment must be carried out before processing to make the ingredients of raw materials meet the processing requirements.

(2) Desilting cleaning is mainly to remove sediment and foreign matter on the surface of potato raw materials.

(3) Peel and separate the potato skins and spray the color protection solution to prevent oxidative browning on the surface of the peeled potatoes.

(4) Trim The peeled potatoes are manually trimmed to remove the unremoved potato skin, bud eyes, unevenness and green parts.

(5) Cut into strips According to different specifications, cut the potatoes into square strips, and the strips are required to be neat and straight.

(6) Fractional separation of short strips and debris generated during processing to improve yield.

(7) Dehydration and drying adopts a mesh belt drying and dehydration device to remove the surface moisture of french fries and prepare for the next frying process.

(8) French fries are fried in hot oil for a short time, then fished out, and the excess oil is filtered off, so that the unique potato aroma of french fries can be fried.

(9) Quick-frozen fried french fries are pre-cooled and sent to quick-freezing equipment for deep-freezing and quick-freezing, so that the crystallization in the French fries is uniform, which is convenient for long-term freshness-keeping storage and maintaining the original flavor.

(10) Bag-by-bag refrigeration can be carried out manually or by automatic equipment. During the packaging process, the time should be shortened as much as possible to avoid moisture absorption and thawing of quick-frozen french fries, which will affect product quality. Refrigerate immediately after packaging.

1. Loading elevator - automatic lifting and loading, convenient and fast, saving manpower.

2.Washing and peeling machine - automatic potato cleaning and peeling, energy saving.

3.Sorting conveyor line - remove the rotten and pitted parts of potatoes to improve the quality.

4. Cutter-adjustable in size.

5.Washing-Clean the starch on the surface of french fries.

6.Blanching machine - inhibit the activity of active enzymes, and protect the color.

7.Rising and cooling machine - quickly cool the french fries and maintain the color and taste.

8. Dewatering machine - the air-cooling effect removes the surface moisture of the potato chips, and transports them to the fryer.

9.Frying machine - frying for coloring, and optimizing the texture and taste.

10.Deoiling machine- to remove oil and cool down - blow off excess oil on the surface, and fully cool down the potato chips so that they can enter the flavoring machine.

11.Tunnel freezer -quickly freeze french fries to maintain their color and taste.

12. Packing machine - according to the weight of the customer's packaging, automatic packaging of potato chips.

Quick-frozen french fries, frozen french fries, semi-finished french fries, snack food french fries