Automatic French Fries Production Line Potato Chips Making Machine Small Scale Semi-Automatic Fried French Fries Making Machine

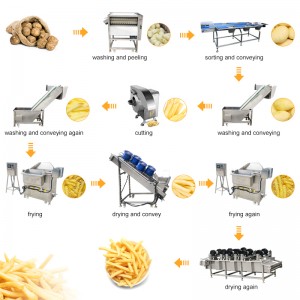

Working principle of French Fries Production Line

1.Peeler: cleaning and peeling process at one time, high efficient and low consumption.

2. Cutter: cut into strip,flake and julienne shape, adjustable cutting size

3. Blancher: do rinsing and color protection of the cut potato chips.

4. Dehydrator: centrifugal dehydration, reduce the time when drying, and improve the taste of the potato chip.

5. Fryer: keeps the potato chips quality and taste.

6. Deoiler: use the centrifugal, overcome the shortcoming of botheration.

7. Flavor Machine: make the potato chips turning even, use the spray type to add the seasoning, not easy to break.

8. Vacuum package machine:when packing, put into nitrogen, can avoid break of the potato chips. And it can aeration, package, and type the date at one time.

Classification and specific introduction of quick-frozen french fries production line:

Raw potatoes →Loading elevator→ Washing and peeling machine → Sorting conveyor line →Elevator→Cutter →Washing machine →Blanching machine→Cooling machine → Dewater machine → Frying machine →Deoiling machine→Peeking conveyor line → Tunnel freezer →Automatic packing machine

Quick-frozen french fries, frozen french fries, semi-finished french fries, snack food french fries